What is a double girder semi-gantry crane?

A semi-gantry crane features a distinctive structural configuration, operating with one leg supported by ground-mounted rails and the opposite side moving along overhead runway rails, much like an overhead bridge crane. This design effectively combines the functionalities of a full gantry and a bridge crane.

Features of Double Girder Semi-Gantry Crane

Key Characteristics:

Space Optimization: Utilizes existing workshop columns and elevated rails, maximizing free floor space.

Compatible Operation: Can be integrated to work in conjunction with bridge cranes within the same facility.

Economic Efficiency: Requires fewer support structures compared to full gantry or standalone bridge cranes, reducing overall investment.

Ideal Applications:

Handling light to medium loads (e.g., goods loading, equipment servicing) across manufacturing plants and docks.

Suitable for diverse settings, from small workshops managing several tons to heavy industrial applications requiring hundreds of tons of capacity.

Installation Consideration:

Adequate clear space and well-maintained, unobstructed ground tracks are essential for safe and efficient operation, as one side of the crane travels directly on floor-level rails.

Key Benefits of Our MGB Double-Girder Semi-Gantry Crane with Hook

Robust & Efficient Engineering

Durable Construction: Fabricated from high-tensile steel (Q235B/Q345B) for superior strength and load-bearing performance.

Precision-Main Girder: Features a CNC-machined, box-section girder for enhanced longevity and operational precision.

Hybrid Rail System: Employs a dual-track setup with ground rails on one side and overhead workshop rails on the other, optimizing spatial use and operational flexibility.

Enhanced Safety Systems

Protective Mechanisms:Incorporates overload and low-voltage protection to prevent equipment failure and enhance workplace safety.

Collision Prevention: Equipped with anti-collision alarms, rail clamping devices, and hoist limit switches.

Electrical Safety: Includes phase protection and self-monitoring circuits with integrated travel limit switches.

Superior Operator Experience & Control

Ergonomic Cabin: Designed with a closed cab, adjustable seating, insulated flooring, reinforced glazing, and optional air conditioning or fire safety equipment.

Flexible Control Modes: Offers a choice of pendant station, wireless remote control (F21/F23/F24 models), or variable frequency drive (VFD) systems.

High-Capacity Lifting Performance

Versatile Hook Assembly: Available with single or double hook configurations, featuring swivel bearings and wire rope protective covers.

Hoist Safeguards: Includes Class F insulation, single or dual-speed motor options, and integral overload limiters.

All-Weather Durability & Serviceability

Outdoor Readiness: Critical electrical and lifting components are shielded with protective rain covers.

Corrosion Resistance: Treated with an epoxy zinc-rich primer, suitable for demanding environmental conditions.

Maintenance-Friendly:Employs a modular design philosophy, ensuring easy access to components for inspection and repair.

Adaptable for Various Industries

Broad Capacity Spectrum: Capable of serving numerous sectors, including general industry, construction, and warehousing.

Optional Upgrades: Additional features such as climate control, communication systems, or custom alarms can be provided.

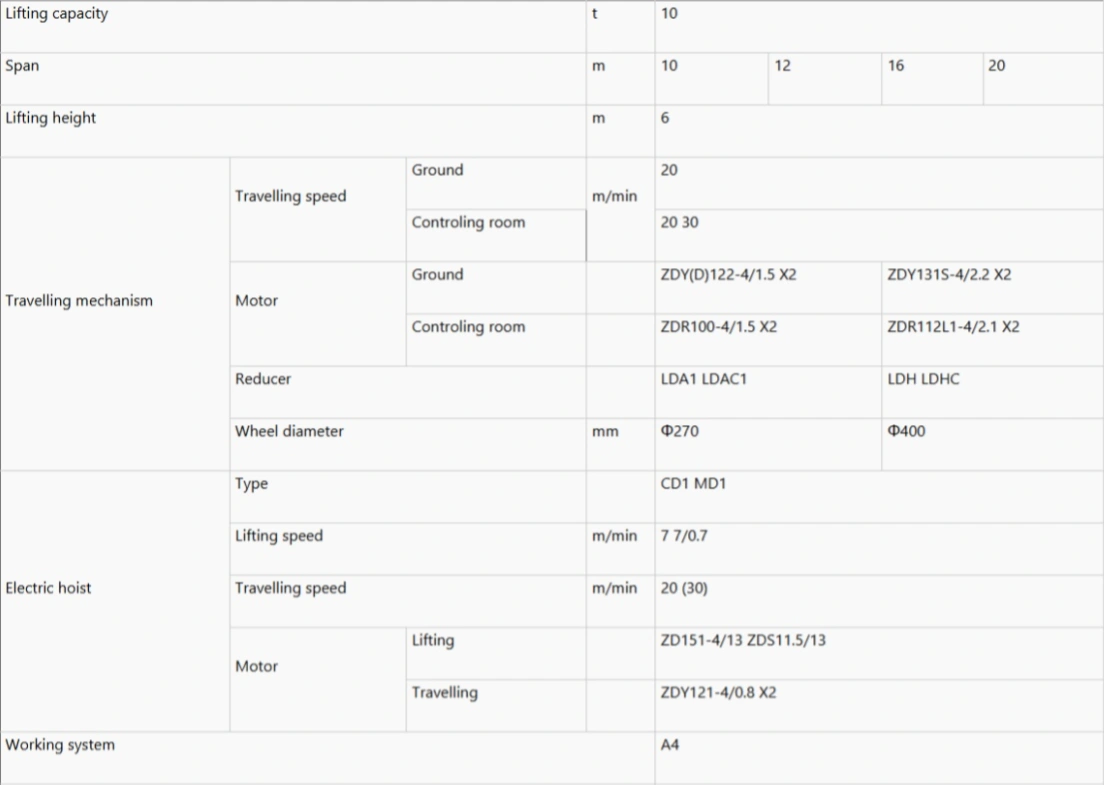

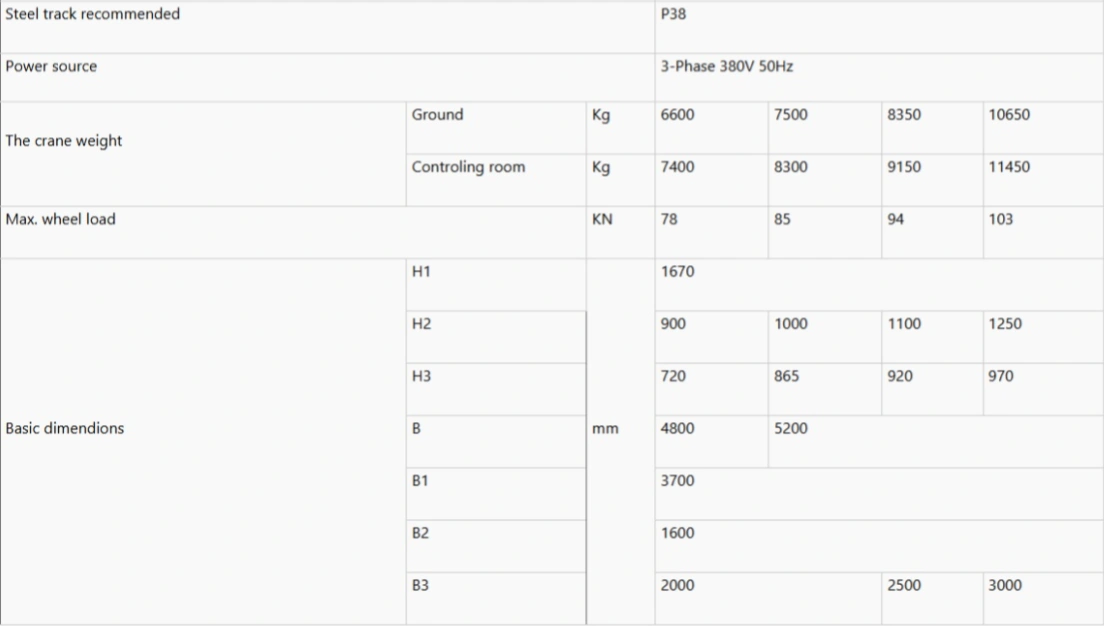

Technical Parameters of double girder semi-gantry crane?

Why Partner With Us?

Proven Track Record: We annually supply over 4,000 gantry crane units, with a strong export presence to markets including the USA, Russia, and Australia.

Recognized Quality: Holder of 120+ industry awards and certifications, affirming our status as a high-tech enterprise.

Expertise & Scale: Our extensive manufacturing facilities span 1.6 million+ square meters, supported by a skilled workforce of over 4,200 professionals.