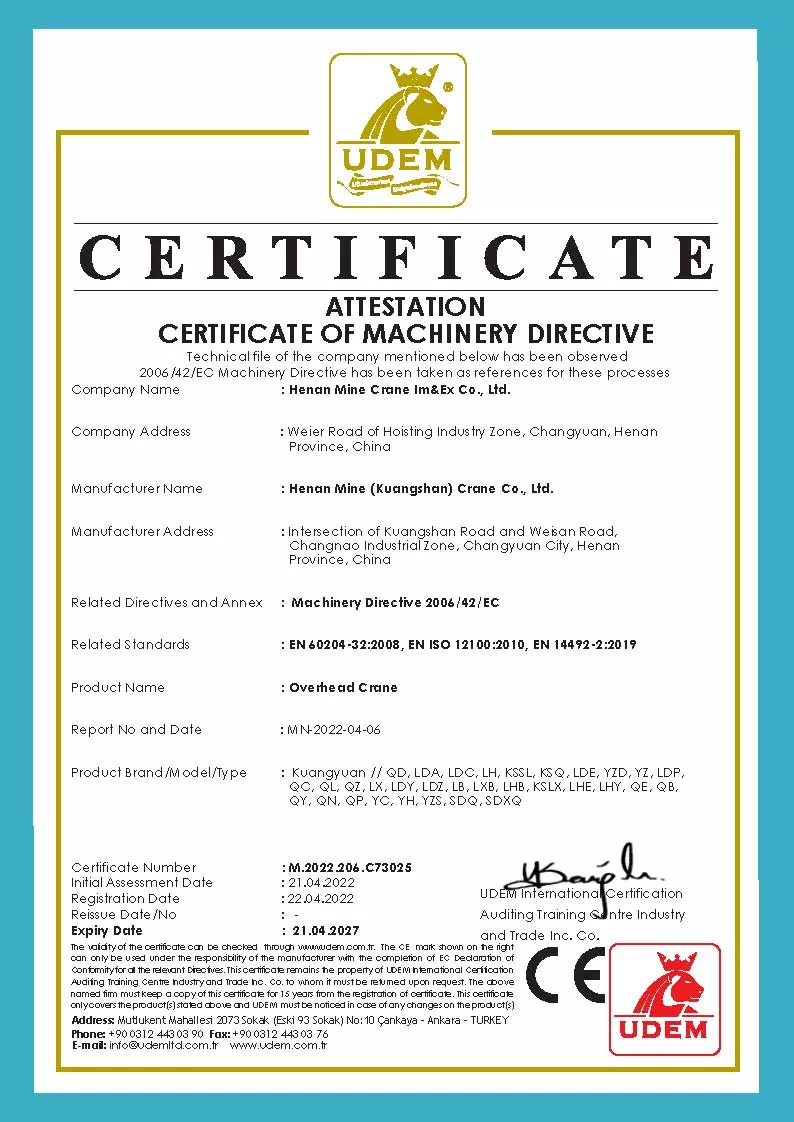

Introduction of Casting Crane

In today's demanding steel production environments, foundry cranes are required to operate with increasing frequency. This necessitates cranes that are not only robust and reliable but also engineered with fail-safe mechanisms to prevent catastrophic failures. Our foundry cranes are designed to ensure that, even in the event of a component malfunction, the ladle remains secure against tipping or falling. Featuring a straightforward structural design, our cranes allow for rapid maintenance and servicing, minimizing downtime and supporting uninterrupted steel manufacturing processes.

Features of Casting Crane

Core Safety Systems

We prioritize your operational safety and financial protection above all else. Our QD-type double girder overhead cranes are built with integrated safety systems, and we strongly recommend all operations adhere to strict Standard Operating Procedures. While our cranes come with comprehensive standard protections, we also offer customization to meet your specific safety requirements—all with the goal of delivering a fully secure working environment.

Key safety features include:

Visual & Audible Alert System: Flashing beacon and alarm siren.

Anti-Collision Sensor: Wireless infrared detection system.

Hoist Upper Limit Switch: Prevents overwinding.

Travel Limit Switches: For controlled crane movement.

Undervoltage Protection: Guards against power dips.

Overcurrent Relay: Protects against motor overload.

Phase Sequence Monitor: Ensures correct power supply connection.

Instant Stop Control: Emergency shutdown function.

Heavy-Duty Buffers: High-grade spring absorbers for impact reduction.

Technical Parameters of Casting Crane

Lifting Capacity: 5 ~ 550 tons

Work Class: A6, A7

Crane Span: 10.5 ~ 31.5 meters

Lifting Height: 6m, 9m, 30m or customized

Raged voltage: Three-phase AC 380V 50HZ