Introduction of Electromagnetic Hanging Beam Overhead Crane

This heavy-duty crane integrates a 360° rotatable electromagnetic lifting beam, engineered for efficient loading, unloading, and horizontal transfer of steel plates, sections, coils, and similar materials. It is ideally suited for steel plants, shipyards, ports, storage yards, and other fixed-span locations, both indoors and outdoors.

To match specific operational needs, the system can be configured with a range of advanced options, including:

Precision speed control (with a ratio of 1:10 or higher)

Overload protection with instant alarm

Remote control operation

Integrated PLC control and automated fault diagnostics

Real-time data display, recording, and printout systems for all mechanisms

The hook and carrier beam feature a detachable connection. The beam can be outfitted with electromagnetic chucks, material clinchers, or custom-designed lifting hooks, and is available in two orientations—parallel or perpendicular to the main girder. This design contributes to improved anti-swing performance during operation. Specialized lifting attachments, including suction cups and clamps, can also be mounted beneath the beam.

Features of Electromagnetic Hanging Beam Overhead Crane

Key Advantages

Lightweight & Robust Design: Engineered for strength without excess weight, enhancing durability and performance.

User-Oriented Operation: Simplified controls ensure ease of use across various skill levels.

High-Performance Magnetic Force: Powerful electromagnets provide secure and reliable material handling.

Enhanced Safety Systems: Built-in safety mechanisms ensure stable and accident-free lifting operations.

Advanced Customization: For demanding applications, an extractable and fully rotating (360°) electromagnetic beam system is available.

Versatile Handling Solution: Designed as a specialized crane using a rotating electromagnetic beam, it lifts and transports heavy loads via integrated electromagnets for maximum efficiency.

Technical Parameters of Electromagnetic Hanging Beam Overhead Crane

Frequently Asked Questions

Q1: What details are needed when requesting a quote?

A1: Please share as much detail as possible—such as lifting capacity, lifting height, span, operating voltage, and any special requirements or drawings. This helps us provide an accurate solution.

Q2: Do you offer custom crane solutions?

A2: Absolutely. As a manufacturer with an in-house engineering team, we specialize in creating tailored designs based on your specific operational needs.

Q3: Is technical installation support available?

A3: Yes. We have a professional installation crew with international experience. If you require on-site assistance, let us know in advance so we can arrange the best support plan.

Q4: How is product quality assured?

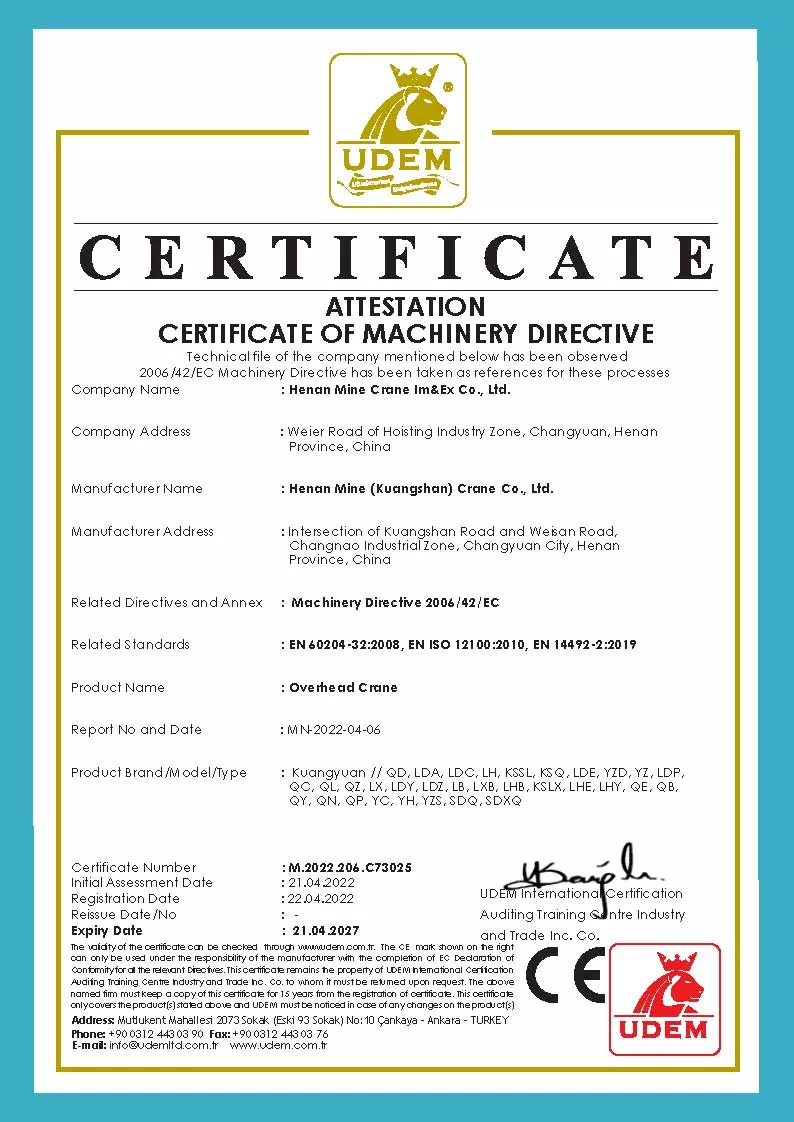

A4: We perform strict quality checks throughout manufacturing and conduct thorough pre-shipment testing. A quality certificate is provided with each shipment.

Q5: Which international certifications does your crane hold?

A5: Our cranes are certified by leading international bodies, including CE, ISO, GOST, SGS, TUV, and BV.