What is a QD hook bridge crane?

Our QD series double girder overhead crane is a premium lifting solution, built for demanding industrial applications. Its robust construction includes a welded box-type main girder, end carriages, a high-performance hoist trolley, and a fully integrated electrical control system. Designed for versatility, it supports various lifting attachments such as hooks, grabs, or electromagnets to suit your operational needs.

Features of Hook Overhead Crane

Optimized Structural Integrity: The main and end girders are precision-welded into a rigid box-frame design, supporting seamless trolley movement along pre-laid rails. Central bolted joints allow for straightforward segmented transportation and on-site assembly.

Flexible Control Options: Choose from ground-operated pendant control, wireless remote operation, or a fully equipped operator’s cab. Cab options include open or enclosed types, featuring ergonomic seating, enhanced visibility with toughened glass, and optional extras like air conditioning and communication systems.

Smooth & Reliable Motion: Advanced drive systems ensure precise load handling with smooth acceleration and braking, contributing to operational safety and extended equipment service life.

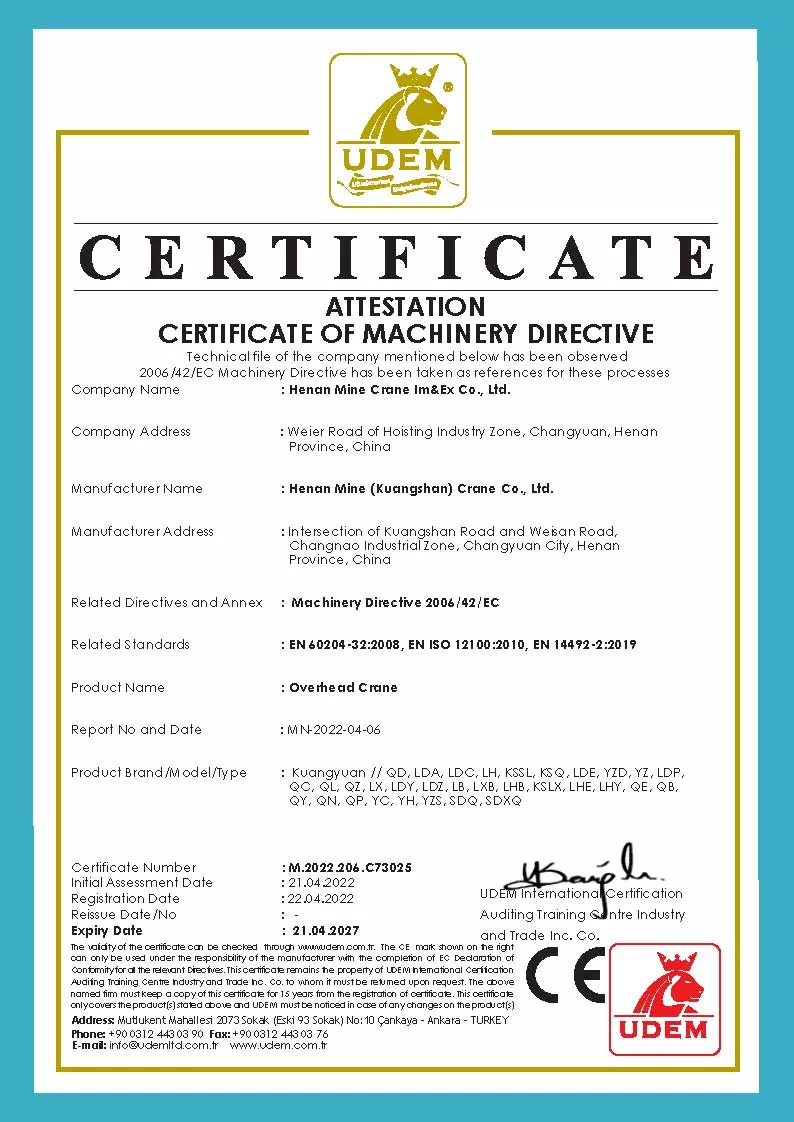

Built-in Safety & Compliance: Each crane includes overload protection, emergency braking, upper/lower limit switches, safety latches on hooks, and durable rubber buffers. All units undergo rigorous pre-delivery testing and come with relevant certification.

Technical Parameters of Hook Overhead Crane

Work Class: A3~A7

Lifting Weight:3~250t

Crane Span:<31.5m

Lifting Height: <22m

Operation mode: ground handle, wireless remote control and driver's cab

Quality Assurance & Custom Engineering:

We employ automated welding and non-destructive testing (NDT) throughout fabrication. Electrical components, including IP54/44-rated motors with Class F insulation, are selected for durability. Our engineering team can tailor the crane to your specific requirements—simply share key parameters such as lifting capacity, span, lifting height, voltage, and working conditions. We also offer matching rail and power supply systems.

Certification & Support:

Our cranes are manufactured in compliance with international standards, including CE, ISO, GOST, and others. We provide end-to-end project support, from custom design and quality control to installation assistance and after-sales service. A one-year warranty covers manufacturing defects, with lifetime support for spare parts at competitive rates.

Let us help you configure the ideal QD crane for your facility. Share your layout and specifications for a tailored solution.