What is an QC electromagnetic overhead crane?

Our QC Magnet Double Girder Overhead Crane is engineered for demanding operations in steel mills, shipyards, ports, storage yards, and warehouses. It excels in loading, unloading, and transporting steel plates, structural profiles, and coiled materials. A key advantage is its ability to handle loads of varying sizes while enabling smooth horizontal rotation for precise positioning.

Features of Electromagnetic Overhead Crane

Key Features & Benefits:

Versatile Access & Control: The control room features flexible entry points with walkway doors located at the end, side, or top for optimal operator access and safety.

Robust Lifting Capacity: The rated lifting capacity incorporates the self-weight of attached equipment, such as electromagnetic discs, ensuring powerful and reliable performance.

Enhanced Safety & Stability: The crane's cross-structured carrier-beam provides exceptional strength and reliability. This design offers inherent anti-sway properties and superior safety. The lower section is engineered to support specialized lifting attachments, including magnetic chucks and lifting tongs.

Critical Operational Note: For safe operation with an electromagnetic disc, the hook's rotary mechanism must be securely locked using screws to prevent any rotation during use.

Technical Parameters of Electromagnetic Overhead Crane

Span:10.5~31.5m

Power Source: 3 Phase 380V 50hz

Lifting speed: 1-15m/min

Lifting mechanism: Electric Trolley

Trolley running speed:5-40m/min

Crane running speed:5-100m/min

Frequently Asked Questions (FAQ)

1. What information is required for a quotation?

To provide an accurate quote, please share the following details. Technical drawings are highly beneficial.

A. Required Lifting Capacity

B. Crane Span

C. Required Lifting Height

D. Power Supply Specifications

Any other specific requirements are also greatly appreciated.

2. What operating methods are available?

We offer several standard control options to suit your operational needs:

A. Pendant Control Station with push buttons.

B. Wireless Remote Control with push buttons.

C. Operator Cabin Control with a joystick.

You may select the type that best fits your workflow.

3. Is this crane suitable for hazardous environments?

Absolutely. We provide customized solutions, including acid-resistant and explosion-proof models, designed for specific hazardous conditions.

4. Do you supply lifting attachments?

Yes, we can provide a full range of serious lifting tools, including sling belts, clamps, grabs, magnets, and other custom-designed equipment based on your application.

5. What installation support do you offer?

We provide comprehensive installation support. Our experienced engineers can offer on-site guidance and operator training. Additionally, our commercial team is available for visits to facilitate project coordination.

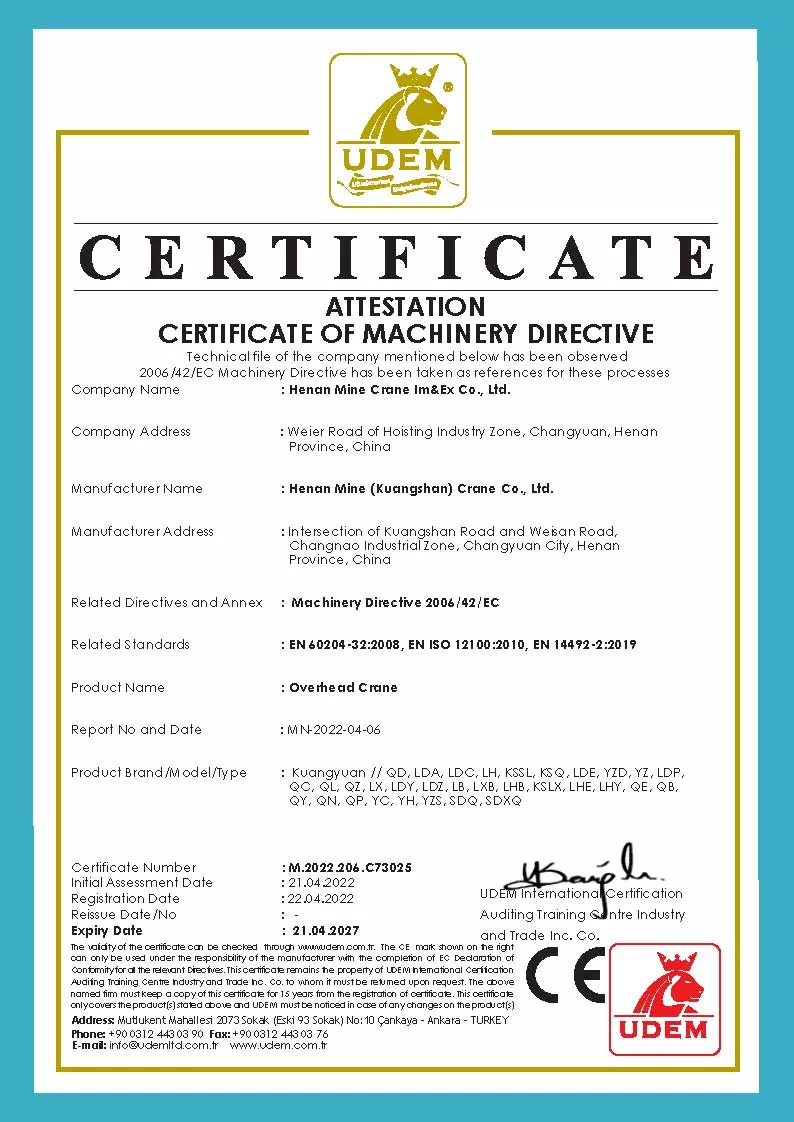

Quality Assurance

Our cranes are certified to the highest international standards, having passed CE, SGS, TÜV, and BV verification. Our manufacturing facility is certified under ISO 9001, ISO 14001 (Environmental Management), and ISO 28001 (Quality, Health, and Safety).