Introduction of QB Clean Explosion-Proof Bridge Crane

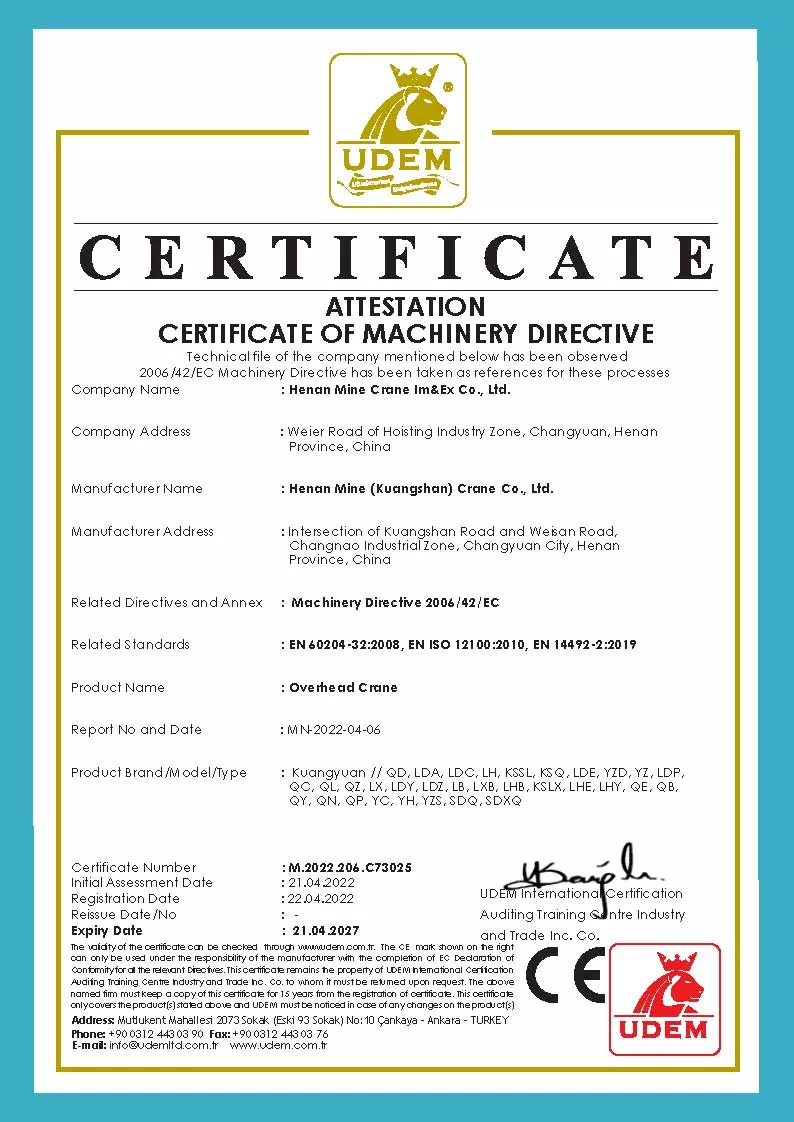

The QB Series Explosion-Proof Crane is meticulously engineered to operate with utmost reliability in volatile settings. Its construction adheres to the stringent "GB3836.2" standard for flame-proof electrical equipment ("Type D"), ensuring complete compliance with the "JB/T5897" specifications for explosion-proof cranes. This model has been officially certified by government-approved testing facilities, carrying the explosion-proof ratings of Exd II BT4 and Exd II CT4.

It is ideally suited for Zone 1 and Zone 2 hazardous areas where explosive gases or vapors of groups IIB or IIC are present, with an ignition temperature classification not below T4. While standard operation is via ground control, the option for cabin control is available for greater flexibility.

Features of Clean Explosion-Proof Bridge Crane

Key Product Advantages:

Robust Electrical Protection: All electrical enclosures are rated at a minimum of IP55, providing superior defense against dust and water ingress.

Durable Motor System: Equipped with motors featuring Class F insulation and a Class B temperature rise rating, this design significantly extends the crane's service life under demanding conditions.

Advanced Load Safety: An electronic overload protection system is integrated, complete with an audible alarm to prevent unsafe lifting practices.

Low-Noise Operation: Engineered for a quieter workspace, the crane generates less than 85 dB(A) of noise even at full load capacity.

Precision Movement Control: Hoisting utilizes a two-speed pole-changing system, while trolley and bridge travel benefit from inverter control for exceptionally smooth and accurate positioning.

Comprehensive Thermal Management: The drive system is protected with thermal safeguards for pole-changing motors and includes three PTC thermistors for the inverter drive.

Fail-Safe Braking: The crane is fitted with a brake that uses an asbestos-free lining, which automatically engages in the event of a power loss.

Design and Safety Compliance:

This crane is developed in accordance with critical Chinese standards, including GB/T3811-2008 (crane design rules), GB6067.1-2010 (safety code for lifting equipment), and JB/T5897-2006 (explosion-proof bridge cranes).

Prioritizing Operational Safety:

Safety is the cornerstone of the QB crane's design. It comes standard with a comprehensive suite of protective devices, such as:

Overload Limiter

Lifting and Travel Limit Switches

Interlock Protection

Buffers and Rail Clearance Plates

Emergency Stop System

Motor Overload Protection

Anti-Collision Device

Main Isolating Switch

Protective Covers and Bus Bar Guards

Additional safety features can be incorporated to meet specific customer requirements, ensuring a tailored and secure lifting solution.

Technical Parameters of Clean Explosion-Proof Bridge Crane

Lifting Weight: 3,5,10,32T

Crane Span: 7.5 ~ 31.5m

Lifting Height: 6m, 9m, 30m or customized

Raged voltage: Three-phase AC 380V 50HZ

Work Class: A5 A6 A7