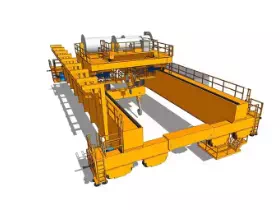

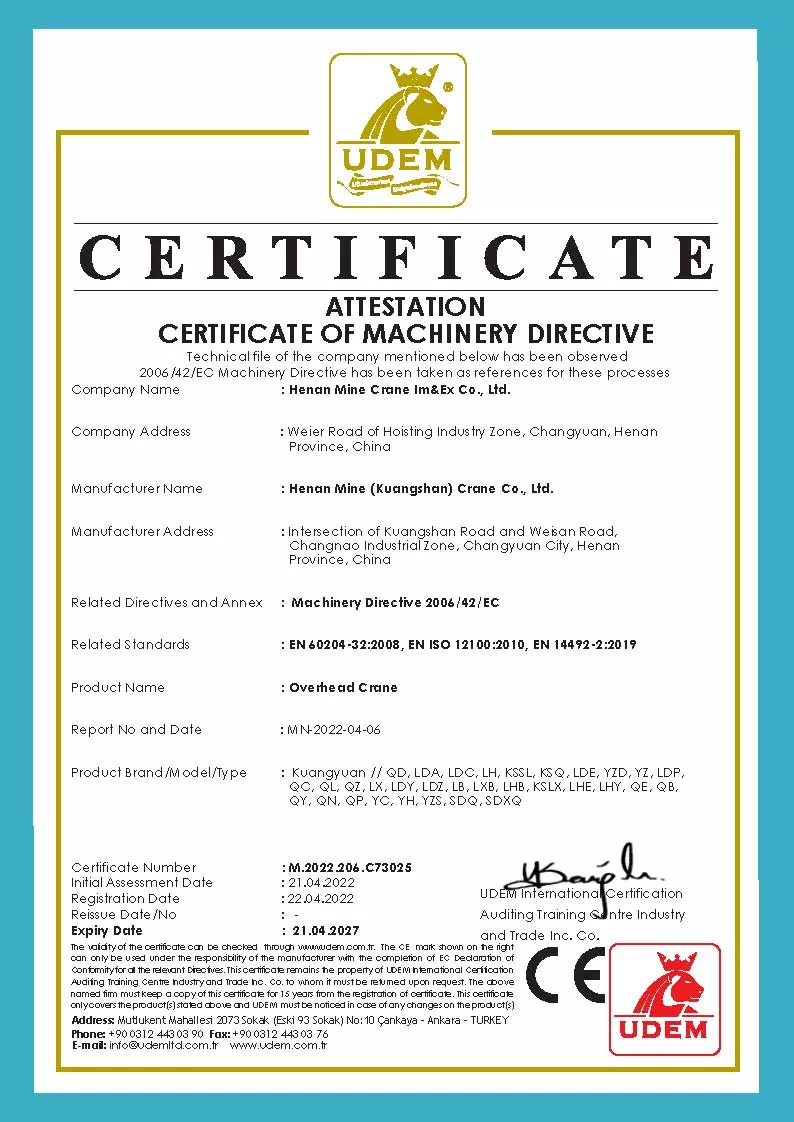

Introduction of Single-Beam Casting Crane

This single girder casting crane is engineered for demanding steel production environments, utilizing a CD/MD series electric hoist as its core lifting mechanism. The hoist travels securely along the I-beam track beneath the main girder, ensuring reliable and precise load handling.

Built to excel in severe conditions, this crane guarantees maximum safety for both personnel and critical processes. It is designed to manage the transfer of molten metal with exceptional efficiency and is available in robust 2 or 4-girder configurations with dual trolleys.

Features of 320t Four-Beam Casting Crane

Core Application Advantages:

Exceptional performance in high ambient temperatures

Maximum operational uptime and reliability

Durability for severe and heavy-duty operating cycles

Long service life with minimal maintenance requirements

Safety-focused hoist systems for critical lifts

Redundant drive systems for enhanced operational security

Design & Construction:

The standard configuration integrates four beams and two trolleys. The main trolley is outfitted with a laminated ladle hook for secure lifting, while the auxiliary trolley handles ladle tilting and supplementary tasks. To ensure resilience, the electrical systems are housed within the main girder and are protected by advanced heat insulation and dedicated cooling devices. This design allows for consistent and effective performance in high-temperature, dusty, and otherwise challenging industrial settings.

For superior control, the primary movements—hoisting, trolley traversing, and crane travelling—employ variable frequency speed regulation with a 10:1 speed ratio. We also provide customizable speed options to align with your specific operational requirements.

Technical Parameters of Single-Beam Casting Crane