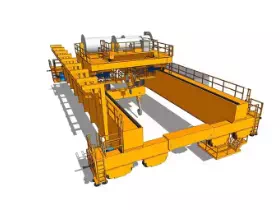

Introduction of New Types Double Girder Overhead Crane

Engineered through the integration and refinement of global technologies, this overhead crane is developed using modular design principles and state-of-the-art computer-aided engineering. It incorporates optimized, dependable design methodologies, utilizing premium imported components, advanced materials, and innovative manufacturing techniques. The result is a high-performance crane distinguished by its lightweight construction, component standardization, energy efficiency, eco-friendliness, minimal maintenance needs, and sophisticated technological integration.

The hoisting system is meticulously designed in full compliance with FEM standards. All design, manufacturing, and quality assurance processes adhere to the latest national standards while also integrating key international norms such as FEM, DIN, and IEC. Key components include precisely machined, hardened gear reducers, durable steel drums, forged wheels, and a smooth variable-frequency drive system.

Features of New Types Double Girder Overhead Crane

Key Product Highlights:

Extended Service Life: Engineered for reliable operation over 30-50 years.

Simplified Setup & Upkeep: Designed for straightforward installation and maintenance.

Robust & Optimized Frame: Features a rational structural design with high rigidity and strength.

Precision Speed Control: Equipped with a variable-frequency drive for accurate and adjustable speed regulation.

Flexible Operation: Offers a choice between cabin control and remote control.

Versatile Lifting Options: Can be customized with various attachments, including lifting magnets, grabs, or C-hooks.

Comprehensive Safety Systems: Includes traveling and overload limit switches, along with other standard safety devices to ensure secure operation.

Structural & Drive System Benefits:

The main beam utilizes a patented, U-shaped, bias-rail box design formed hydraulically from high-grade Q345-B steel. This creates an optimal strength-to-weight ratio, resulting in a lighter, more durable, and aesthetically pleasing structure.

High-strength bolts connect the main and end beams, facilitating easy transport and assembly.

The crane and trolley travel mechanisms employ a compact, European "three-in-one" drive unit. This system, featuring a hardened gear reducer, ensures a small footprint, quiet operation, leak-free performance, and extended service life, which helps lower building height requirements and overall costs.

The trolley features a space-saving, open winch design or a new-style hoist for medium and low capacities. Its power supply system is built for quality, longevity, and easy maintenance.

Full variable-frequency control provides smooth, shock-free starts and stops. It enables heavy loads to be moved at low speeds and light loads at high speeds, significantly enhancing energy efficiency.

Operator Cabin Features:

Ergonomically designed cabin with an attractive exterior.

Integrated connection consoles featuring a comfortable seat and two adjustable control panels.

Includes practical accessories such as an alarm, energy-efficient lighting, a windshield wiper, and sun blinds.

Safety & Protection Systems:

Overload limit protection device

High-grade polyurethane buffers for long-term impact absorption

Crane travel limit switches

Low voltage protection function

Emergency stop switch

Available PLC control system integration

Motor current overload protection

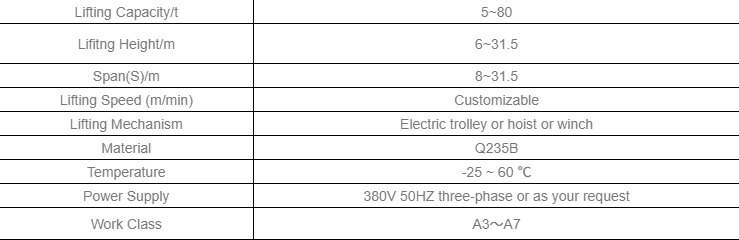

Technical Parameters of New Types Double Girder Overhead Crane

Capacity: 5~80T

Work Class: A3~A7

Span: 8~31.5m

Lifting Height: 6~31.5 or customized

Raged voltage: Three-phase AC 380V 50HZ

Work environment temperature: -25℃~+60℃