Advantages and Features

1. Compact and Flexible Design

Its single-leg structure is ideal for confined spaces, operating on ground rails on one side and elevated workshop rails on the other.

An excellent solution for small-to-medium workshops, warehouses, and production lines that require adaptable lifting solutions.

Design benefits:

Eliminates the need for extensive ground rail systems, enabling unobstructed transport and enhancing operational safety.

Keeps factory floors clear for other vehicles like forklifts.

Simple to install with a short setup time and low initial investment.

Imposes minimal load demands on existing building structures.

2. Robust and Dependable Operation

Built with European-standard engineering for long-term durability and compliance with international certifications (CE, ISO, BV).

The electric hoist provides smooth travel along the I-beam girder for accurate and controlled load positioning.

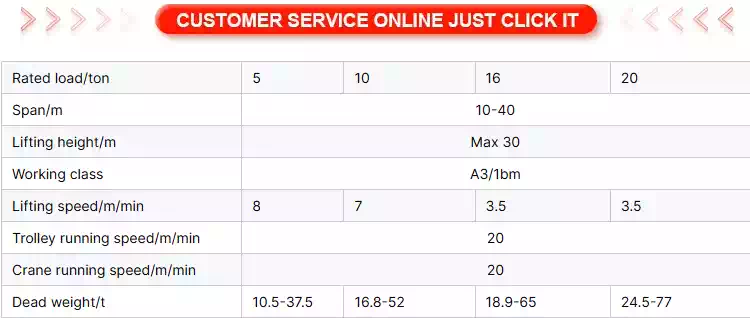

Specifications:

Lifting Capacity: Up to 10 tons.

Span: Up to 15 meters.

Suitable for medium-duty applications.

Features quick installation and low structural impact.

3. Integrated Safety Systems

Equipped with overload protection and low-voltage safety devices to prevent operational hazards.

Safety is further enhanced with anti-collision systems, alarms, and rail clamps. Self-checking circuits and limit switches offer protection against phase loss.

Safety Features:

All motors include thermal overload protection.

Dual-speed or variable frequency control for hoisting.

Controlled speeds for trolley and gantry travel.

Audible and visual alarms for gantry movement.

4. Economical with Simple Maintenance

A straightforward design significantly reduces both installation time and overall costs.

Easy access to components simplifies maintenance and minimizes downtime. Rainproof options are available for reliable outdoor operation in harsh environments.

5. Adaptable Control Options

Operate via pendant or remote control based on your preference. Integrated shields prevent hook clashes for a safer workflow.

Optional Features:

Anti-sway control for precise load placement.

Synchronized lifting systems for dual-hook operation.

Micro-speed and inch-movement for accurate positioning.

Target positioning to automate repetitive lifting tasks.

Why Partner with Us?

Proven Manufacturer: Henan Mine Crane Co., Ltd. is a leading crane maker with over 120 certifications and a export network spanning 30+ countries.

High Production Capacity: We manufacture more than 4,000 gantry cranes and 35,000 single-girder cranes annually.

Global Compliance: Our cranes are CE, ISO, and BV certified, meeting stringent EU and international safety standards.

Commitment to Innovation:* Recognized as a "Hi-tech Enterprise," we focus on R&D to deliver high-performance, durable equipment.

"Quality Makes Brand, Honesty Weaves the Future" – We provide robust, safe, and high-efficiency cranes to meet your specific requirements.